Research & Development

Rest Easier. We'll Make It Comfortable.®

Our products undergo strenuous testing to ensure that you will enjoy years of service without decline in product quality or performance. The following is the National Technical Center Testing Department Procedure Overview of the various tests that each Denver Mattress brand mattress undergoes.

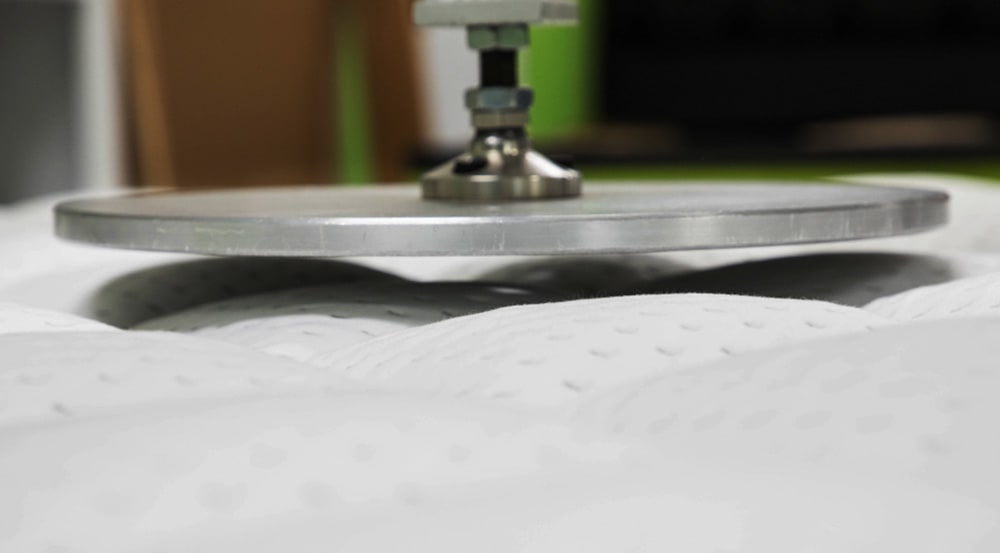

Indention/Load/Deflection Test Machine

The Indention/Load/Deflection (ILD) Test Machine is essentially a tensile/compression tester, specifically designed and built for Leggett & Platt, Inc. Its primary function is to perform firmness evaluations on innersprings, box springs, upholstered mattresses, and bedding sets. A standard mattress evaluation consists of an 8" disk platen being depressed into the sample 4" with the 1/4" increments recorded and summed to determine a firmness value. Typical positions include shoulder zone, geometric center, and calf zone with the geometric center repeated after the conclusion of the physical testing. There are no established pass/fail criteria for this procedure. The typical range for this test is a 10% increase in firmness to a 25% softening from a new to post test condition. A recovery run is conducted in the geometric center after a 24-hour time span with a normal recovery of no change to 10%.

Juggernaut Roller (Rollator)

The Rollator Test Machine is capable of running ASTM Procedure F 1566 Standard Test Method for Evaluation of Innerspring and Box Springs, Section 7 - Durability Test. The Rollator tests consists of a 230 pound 6-sided roller, which rolls across the width of a set of bedding for 100,000 cycles (200,000 passes) at approximately 1,000 cycles per hour. Periodic visual observations are made to report surface flattening and/or damage. Mild flattening represents less than 1/2" change, moderate indicates 1/2" up to 1", and large over 1".

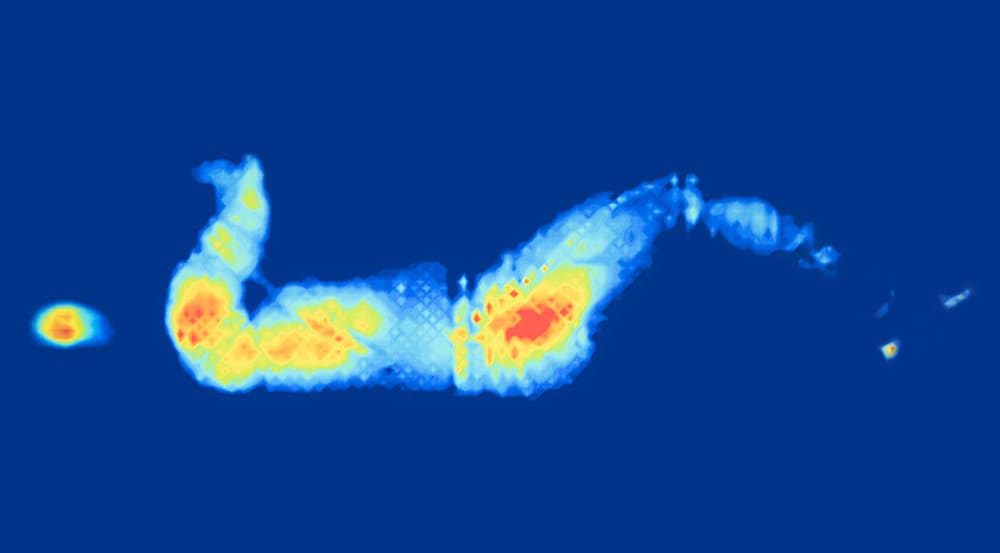

Pressure Mapping

This testing method creates a visual of where pressure points form on the body while sleeping on a mattress. Using this information, the design of our mattresses can be updated to relieve pressure in these areas.

Sonar Measuring System Procedures

The Sonar Measuring System provides an accurate method of measuring the actual height and/or loss of height in a set of bedding. The system utilizes an Ocean Motion Sonar XR-1000 ultra sonic transceiver/receiver. One transducer signals in the vertical plane for height measurements with a second in the horizontal plane for transverse location data. The unit is capable of taking a programmable number of readings over a given distance at the operator’s discretion.

The system’s primary use is in determining height loss in sets of bedding by comparing a new or virgin sample to a post-tested state and again after a 24-hour recovery time span. The one-inch surface flattening or body impression value has become a criterion of sort. Typically, a surface change of 1" or less will pose no problem as far as returns for body impression. When evaluated, a mild surface flattening will represent less than 1/2", moderate flattening up to 1" and large flattening anything over 1". This is not a pass/fail parameter, but rather an indicator that problems might occur.